|

| Position:Homepage >Gypsum board production line |

|

|

|

|

|

|

| #1 transvers system |

Automatic board cutter |

Automatic correcting and marking |

Automatic stacker |

|

|

|

|

| Board turning |

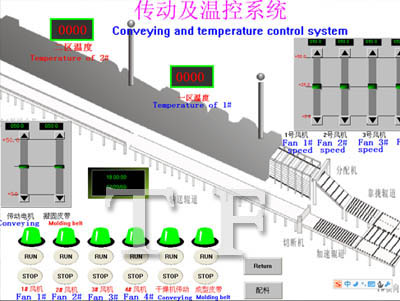

Conveying and temperature control system |

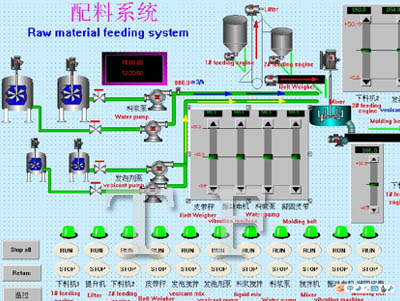

Raw material feeding system |

Heat exchanger dryer |

Production Capacity: |

2 million m2/year 4 million m2/year

5 million m2/year 6 million m2/year

8 million m2/year 10 million m2/year

15 million m2/year 20 million m2/year |

Raw Materials Consumption for per Square Meter Gypsum Board: |

gypsum powder

|

6.8kg/m2 |

Shielding paper |

0.48kg/m2 |

Modified starch |

0.035kg/m2 |

Foaming agent |

0.008kg/m2 |

Glue |

0.005kg/m2 |

Fiberglass (Not need badly) |

0.025kg/m2 |

Electricity |

0.3kwh/m2 |

Water |

4.8kg/m2 |

Heavy oil:11000kcal/kg |

Heat consumption:∽3800kcal/m2 |

Natural gas: 8500kcal/ m3 |

Heat consumption:∽3800kcal/m2 |

|

Main Production Technology Referring to Flow Chart: |

Heat conductive oil drying system adopting natural gas, heavy-oil or coal as fuel |

Specifications of Final Products: |

Thickness: 8mm to 20mm

Width: 1200mm, 1220mm

Length: 2000mm-3600mm |

|

|

|