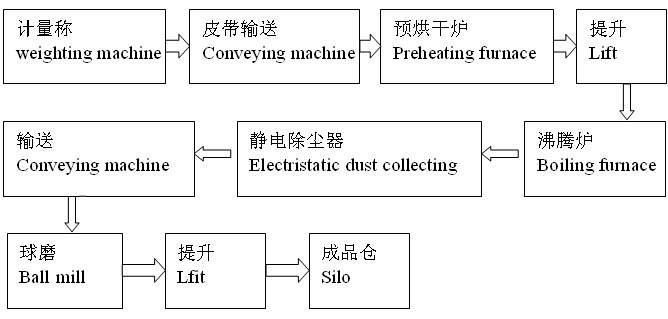

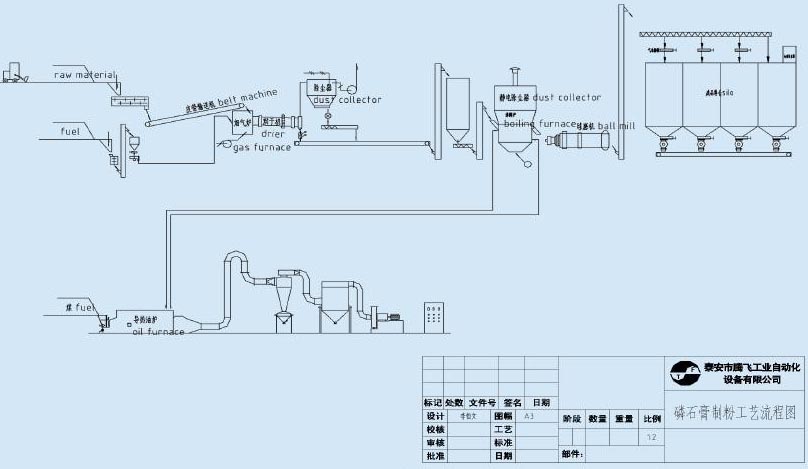

Technology process of phosphogypsum powder production line

Our phosphogypsum powder machine adopts distributed control system (DCS), which greatly reduces the number of operators, thereby effectively reducing labor costs. For the sections which causes dust, high efficient dust collectors are utilized to reduce dust concentration. As a result, our production line now meets the related Euro and U.S. emission standards. In addition, our phosphogypsum powder production line phosphogypsum powder is strictly produced according to the requirements of China's CCC, Euro CE, and U.S. UL systems, so operator safety is highly guaranteed.

In order to help our customers better know our products, our company has established state-of-the-art design offices and laboratories. All projects use three-dimensional drawing, thus providing customers with visualized design. Meanwhile, we have also invested much in purchasing gypsum material testing equipment and inspection equipment for gypsum processing line, which enable us to provide customers with pre-material testing and experimental data for their convenience.

Brief introduction to phosphogyspum

Phosphogypsum are the solid waste industry, and the phosphate fertilizer industry are basic. Wet-process phosphoric acid production process through the generation of sulfuric acid decomposition of phosphate rock slurry extraction, and then filter a phosphate wash system. Filtering process of washing of phosphorous gypsum waste generated at the same time. The general production of 1 ton each produce phosphoric acid of about 5 --- 6 tons of phosphogypsum, the production of 1 ton every 2.5 DAP emissions 5 tons of phosphorus gypsum ---, wet-process phosphoric acid production in our country is about more than 100 million tons, With the high concentration compound fertilizer in China in recent years the rapid development of industry in each category by the phosphate chemical enterprises Phosphogypsum discharged near about 20 million tons.

The phosphogypsum has the following characteristics: l. Phosphogypsum Most are attached to higher water or in wet slurry was discharged slag, general, and its contents are attached to the water at 10 --- 40% or more of the individual 2. Phosphogypsum smaller particle size, particle size generally at between 5 --- 300-micron, the production of gypsum powder when broken can be saved, the cost of grinding, but it can also generate a lot of dust, increasing the cost of removal. 3. Phospho gypsum generally more complex ingredients, but contain less hardening of the gypsum hydration properties have a greater impact on the chemical composition, PH value neutral and not acidic. To the effective use of chemical gypsum greater degree of difficulty. Phosphogypsum at, the active ingredient content of gypsum are generally higher, up to 75 --- 95%, equivalent to more than two gypsum content of the active ingredients. If one of its active ingredient rather than the content of the harmful effects of impurities, industrial by-product gypsum plaster can be as high quality raw materials.

Therefore, if the use of appropriate technology and equipment, be able to eliminate harmful ingredients in Phosphogypsum the impact of phosphogypsum will become a low-cost, high-grade, high-quality raw materials of environmental protection.

|